Developers were taking no gambles with the design of the MGM National Harbor on the outskirts of Washington, D.C. Located a short 12-minute ride from Capitol Hill, the $1.4 billion hotel and casino complex sits atop an elevation, across from the restaurants, boutiques and hotels of National Harbor overlooking the Potomac River and Alexandria, Virginia on the other side.

Going All-In with MaxumStone

Given its stately location, this modern MGM resort complex was built with and eye on first-class amenities, inside and out. The design team delivered, producing an award-winning LEED-certified casino, entertainment complex and state-of-the-art event center. Inside is a fascinating mecca, complete with a casino, hotel, restaurants, convention facilities, boutiques and even a conservatory. The outside features a 1.7 million square foot exterior clad in tiered, angled precast concrete panels that pay homage to the historic monuments a few miles downriver along the National Mall.

Of course, an elite campus of that scale demands a premium quality wall system. And that’s why the property’s developers, Peterson Companies, chose a big block MaxumStone gravity retaining wall from York Building Products.

Tall Wall Advantages

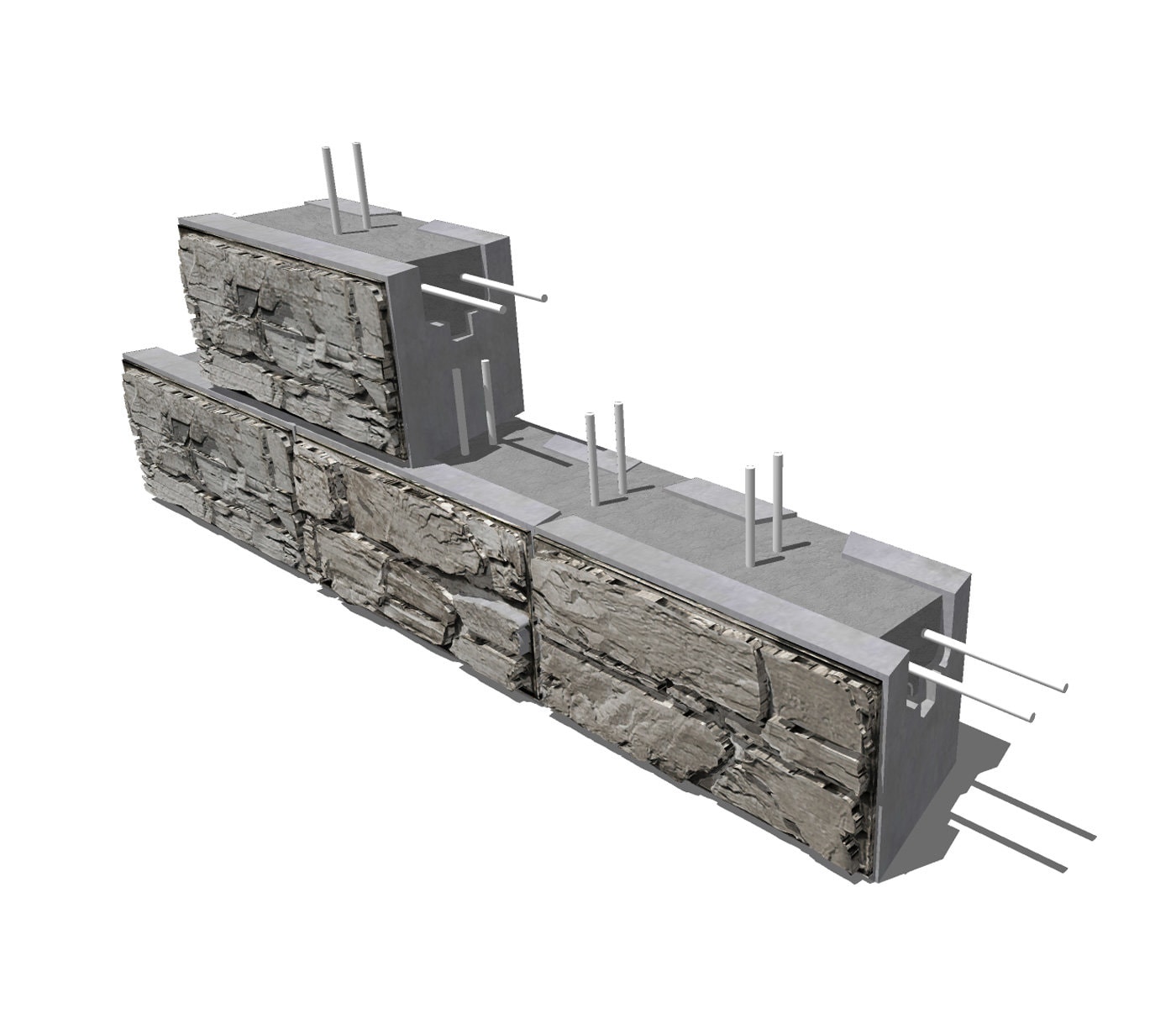

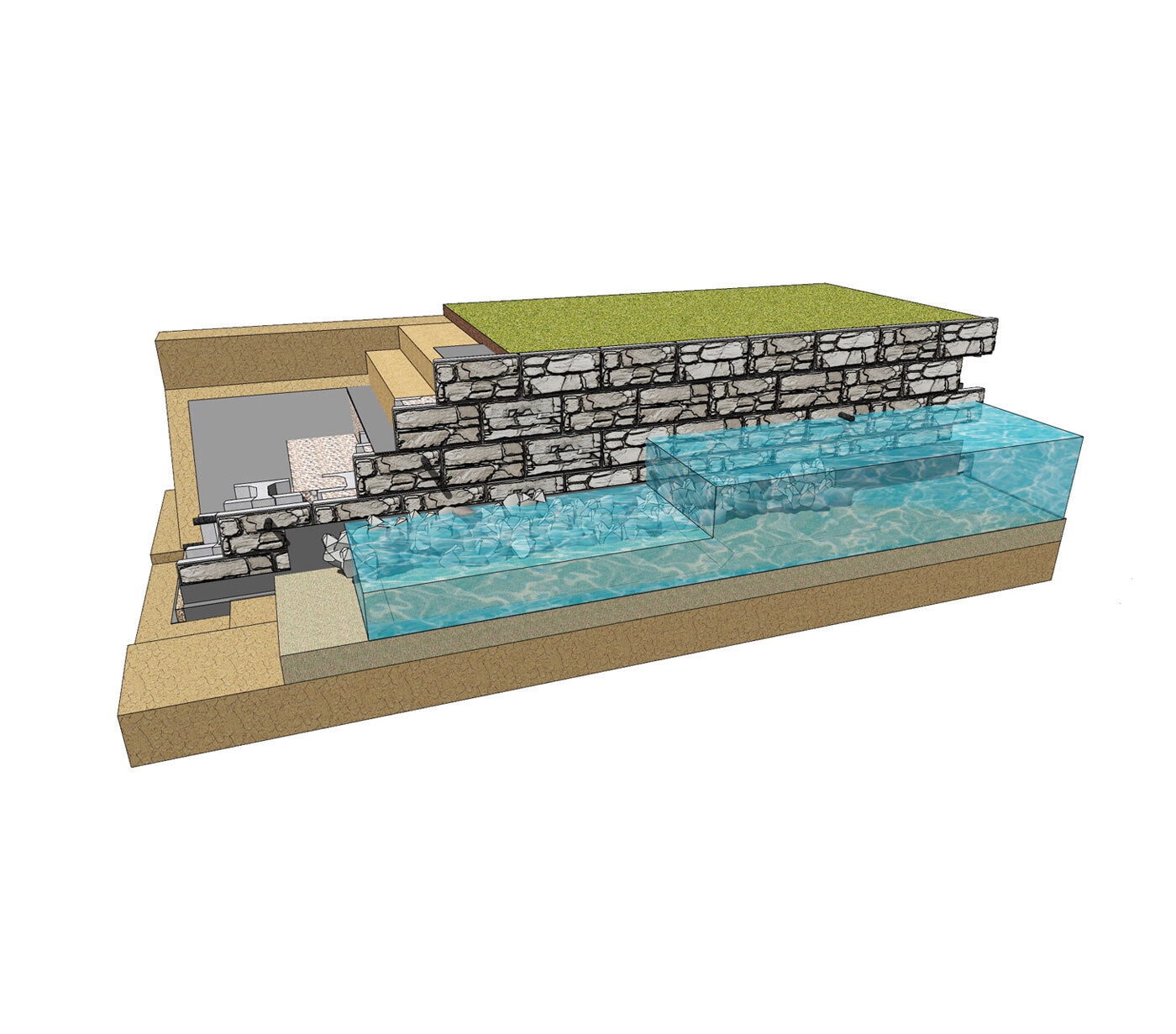

Always an elegant choice, the MaxumStone hollow core block system forms a 763 sq. meter retaining wall that shores up a parking lot situated 22 feet above the roadway. Completed in 2016, the retaining wall project came with some special provisions that made MaxumStone the perfect solution.

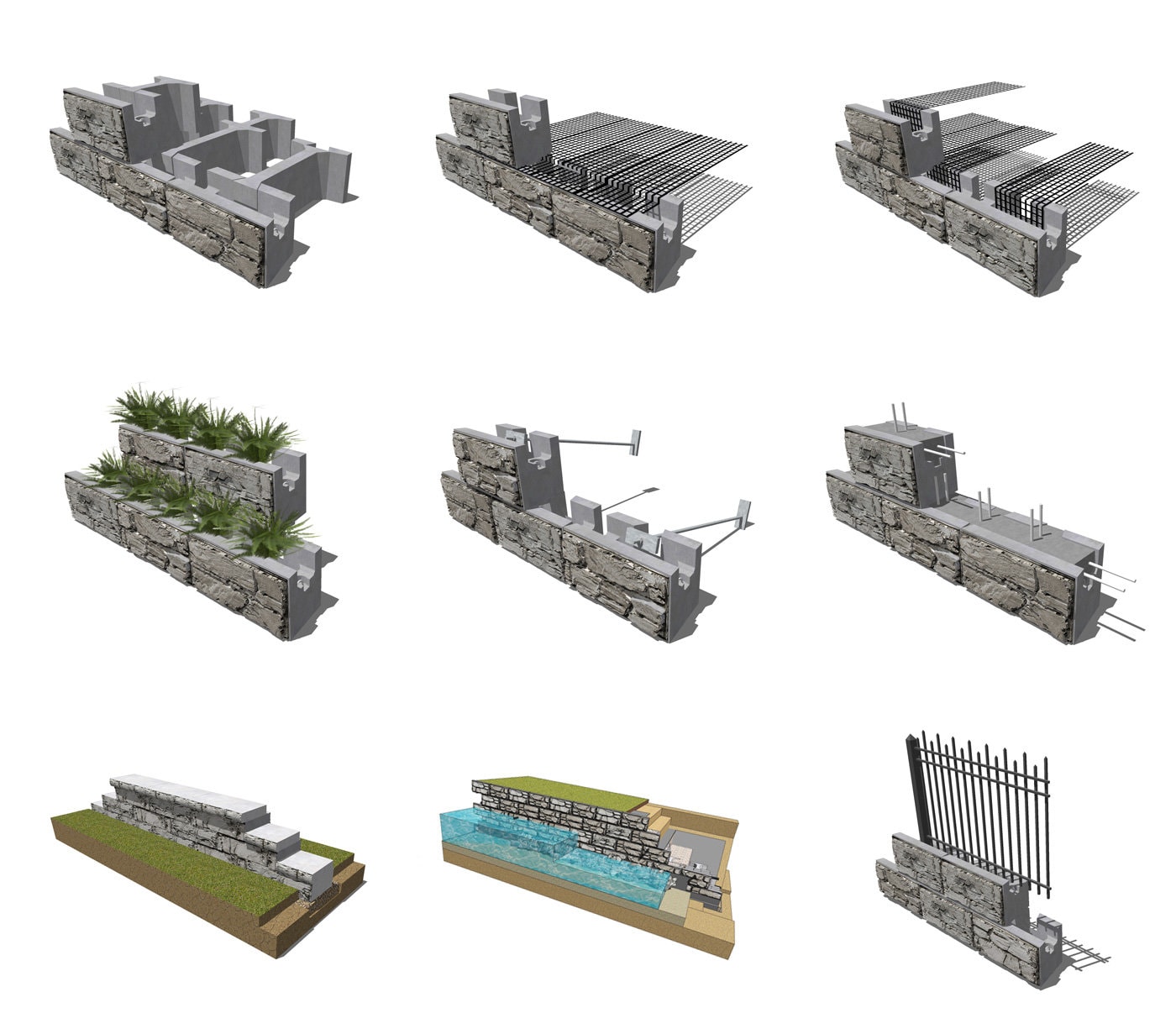

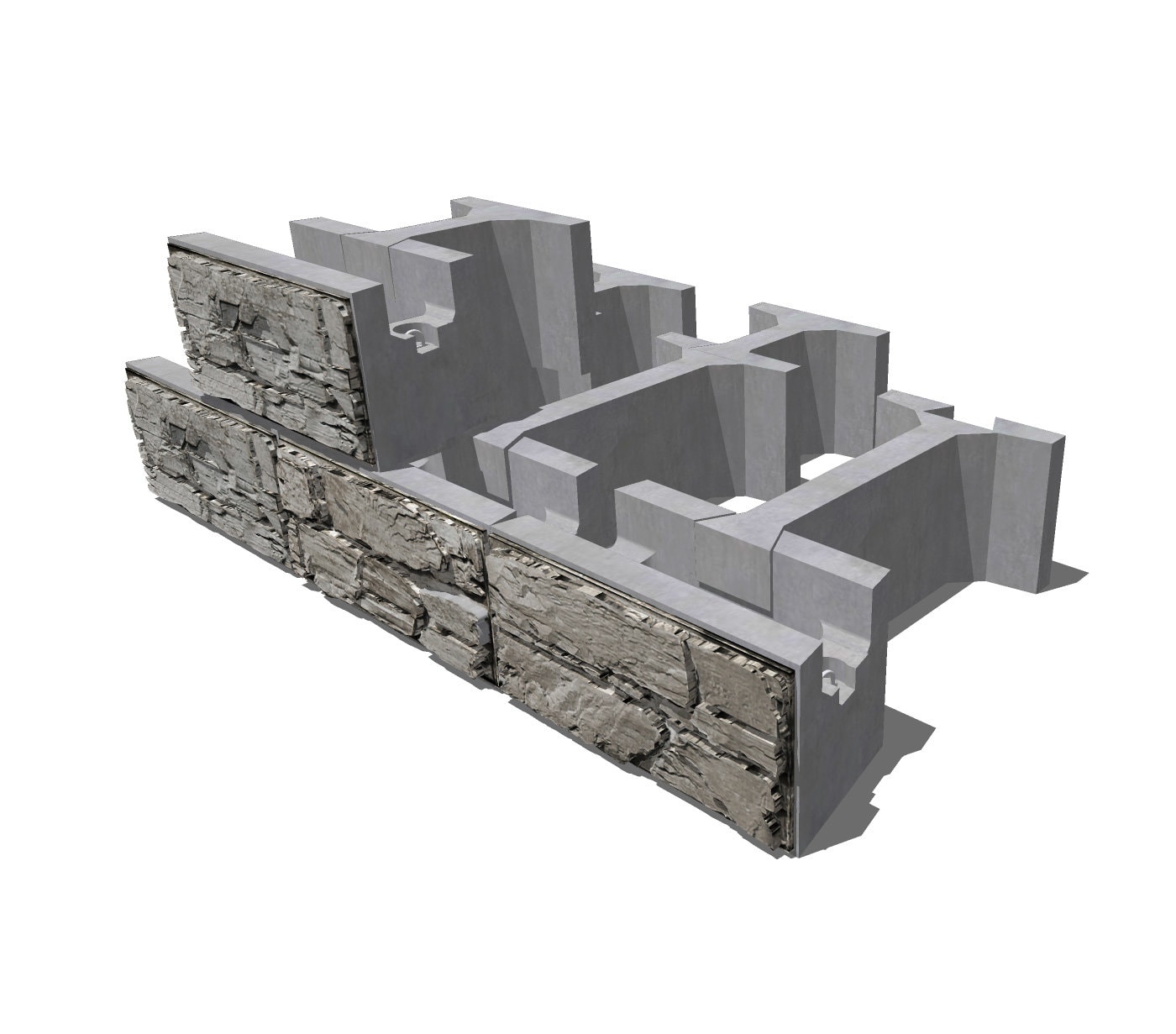

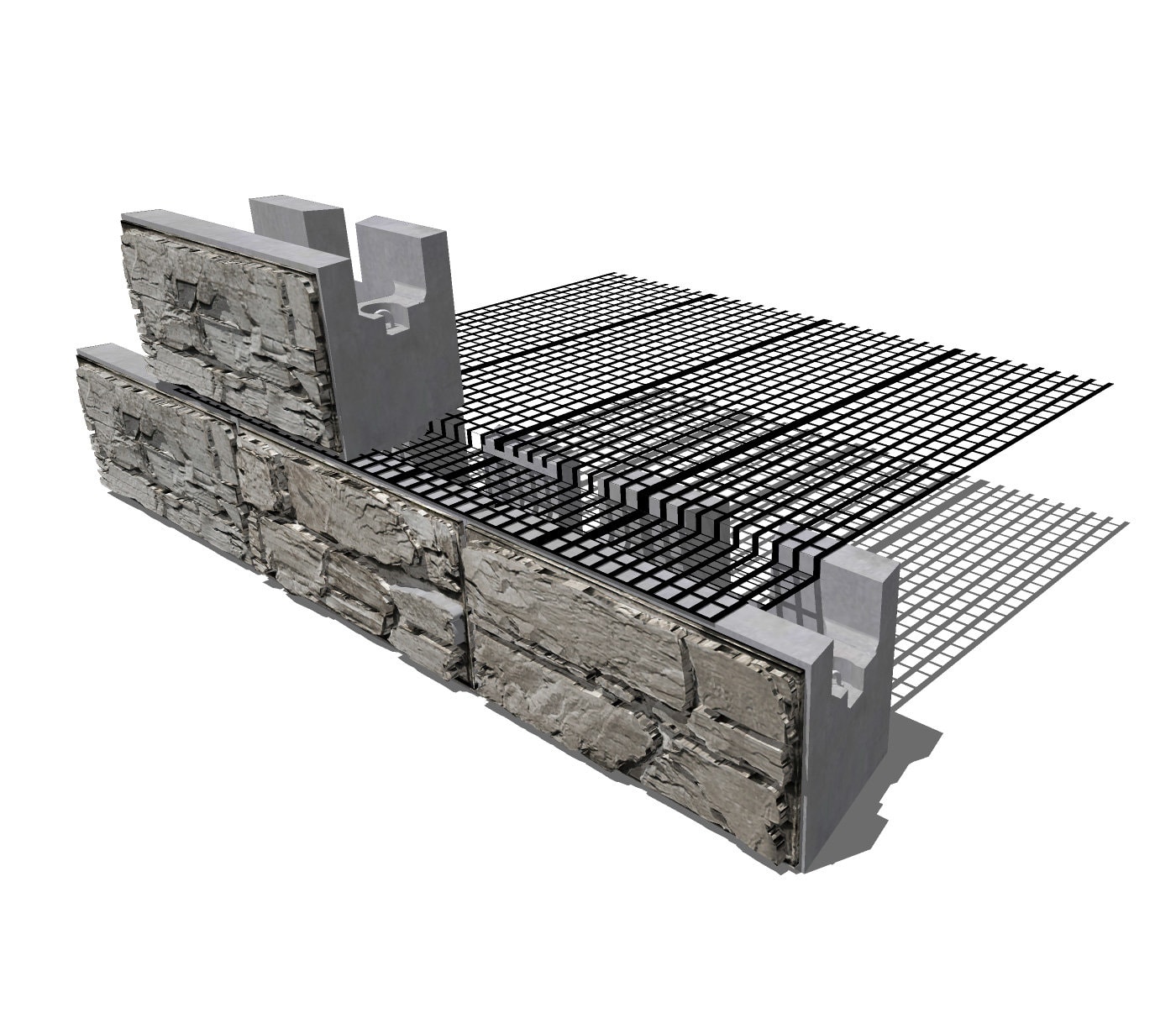

The project’s engineer, Geo-Technology Associates, Inc., wanted to design a wall system without geogrid so that any future excavation or building expansion would not affect the structural integrity of the wall. The MaxumStone extender system enabled the wall to rise 7.3 meter tall (including embedment) while only requiring a depth of 10 feet.

The big block units, which are 2-feet deep, are supported by the extender system, which slides into the back side of the unit. Extender lengths of 2 feet and 4 feet provide the wall designer with flexibility to optimize excavation space while creating a big block high-rise wall. In this instance, the 7.3 meter height required two 1.2 meter extenders added behind the block, providing a compact 3 meter deep width at the tallest section of the wall.

Eco-Friendly Gravity Retaining Walls

MaxumStone’s sustainable design also contributes to the LEED-certified ethic of the MGM campus. That’s because MaxumStone wall systems are sustainable by design. The hollow core system uses 40% less concrete than a traditional big block wall, which has several eco-friendly benefits.

The innovative MaxumStone extender unit system uses soil reinforcement instead of additional concrete, thereby reducing the carbon footprint of the manufacturing process. The lightweight blocks also mean reduced carbon from transportation to the site. Once on site, installation requires smaller equipment and less labor, therefore providing additional savings.

This project was a major success thanks to everyone who helped from start to finish, including local MaxumStone manufacturers York Build Products, contractors The Whiting-Turner Contracting Company, designer Geo-Technology Associates Inc. and the excellent installation by Griffith Brothers, Inc.

MaxumStone’s strong, beautiful retaining walls were the dealer’s choice for MGM National Harbor and will surely be a safe bet for decades to come.

Photos: York Building Products.